Metal Laser Marking Machine

Metal Laser Marking Machine Specification

- Marking Speed

- 7000 mm/s (Max)

- Condition

- New

- Laser Type

- Fiber Laser

- CNC

- Yes

- Cooling Mode

- Air Cooling

- Control Software

- EZCAD

- Accuracy

- 0.01 mm

- Dimensions

- 730 mm x 500 mm x 770 mm

- Positioning System

- Red Light Pointer

- Minimum Line Width

- 0.01 mm

- Wavelength

- 1064 nm

- Input Voltage

- AC 110V/220V 10%, 50/60Hz

- Minimum Character

- 0.15 mm

- Supported Materials

- Metals (Aluminum, Stainless Steel, Copper, Gold, Silver, Titanium, etc.), Some Plastics

- Supported File Formats

- AI, PLT, DXF, BMP, JPG, etc.

- Repetition Frequency

- 20 kHz 100 kHz

- Operating Temperature

- 10C 35C

- Laser Life Span

- >100,000 Hours

Metal Laser Marking Machine Trade Information

- Minimum Order Quantity

- 1 , , Unit

- Supply Ability

- 10 Units Per Month

- Delivery Time

- 1 Months

About Metal Laser Marking Machine

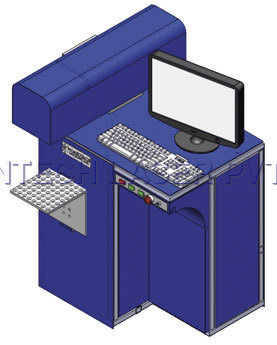

Metal Laser Marking Machine

We are one of the leading manufacturers, exporters and suppliers of Metal Laser Marking Machine used for various industrial applications including High precision Hallmarking application. This is highly appreciated for optimum strength, less maintenance, easy installation and longer functional life. The entire range of Metal Laser Marking Machine is available in various specifications to meet the application requirements of the clients. Our team of quality controllers tests this laser marking machine on various parameters to meet the defined international norms.

Exceptional Marking Precision

Achieve unparalleled detail with a minimum line width of 0.01 mm and character size as small as 0.15 mm. The cutting-edge fiber laser ensures accuracy and clarity on a wide range of metals and certain plastics, supporting complex logos, serial numbers, and intricate patterns for premium product marking.

User-Friendly Operation and Versatility

Equipped with intuitive EZCAD software and a red light pointer for precise positioning, this machine supports common file formats such as AI, PLT, DXF, BMP, and JPG. Its air-cooled system ensures smooth operation within temperatures of 10C to 35C, accommodating various industrial environments with ease.

Reliable and Durable Performance

This fiber laser machine boasts a lifespan of over 100,000 hours and operates with an input voltage of AC 110V/220V 10%. Its CNC capability allows for automated processes, while a robust build and straightforward maintenance provide enduring reliability for continuous marking tasks.

FAQs of Metal Laser Marking Machine:

Q: How does the metal laser marking machine achieve such high precision?

A: The machine utilizes a 1064 nm fiber laser, precision optics, and advanced motion control to mark lines as fine as 0.01 mm and characters as small as 0.15 mm, ensuring detailed and accurate marks on metals and select plastics.Q: What materials and file formats are supported by the marking machine?

A: This marking machine supports a wide range of metalsincluding aluminum, stainless steel, copper, gold, silver, and titaniumas well as certain plastics. It can process files in formats such as AI, PLT, DXF, BMP, JPG, among others for flexible design options.Q: When is the ideal time to use this laser marking machine in a production process?

A: The machine is best utilized during the product identification stage or prior to final assembly, ensuring permanent, clear marks for traceability, branding, or compliance before products move through further processing or packaging.Q: Where can this machine be installed, and what are its space requirements?

A: Designed with compact dimensions of 730 mm x 500 mm x 770 mm, the machine is suitable for installation in workshops, production lines, or specialized marking stations with standard AC 110V/220V power supply and a stable operating environment from 10C to 35C.Q: What is the process for using the laser marking machine?

A: Users upload their design files to the EZCAD software, position the workpiece using the red light pointer, configure marking parameters such as frequency and speed, then initiate the marking. The CNC system automates movements for consistent, high-speed results up to 7000 mm/s.Q: What are the key benefits of choosing this metal laser marking machine?

A: Clients gain from extremely precise, fast, and durable marking capabilities, long operational life exceeding 100,000 hours, low maintenance due to robust fiber laser technology, and compatibility with numerous materials and design formatsmaking it a versatile and cost-effective industrial choice.

- Minimum Order Quantity

- 1 , , Unit

- Supply Ability

- 10 Units Per Month

- Delivery Time

- 1 Months

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Laser Marking Machine Category

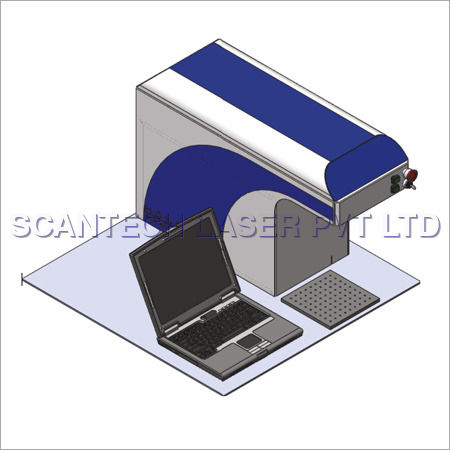

Laser Marking Systems

Minimum Order Quantity : 1 Unit

Condition : New

Cooling Mode : Air Cooling

Laser Type : Laser, Other

Color : Blue

Diode Pump Solid State Laser

Minimum Order Quantity : 1 Unit

Condition : New

Cooling Mode : Air Cooling

Laser Type : Other, Diode Pump Solid State Laser

Advanced Laser Marking Machine

Minimum Order Quantity : 1 Unit

Condition : New

Cooling Mode : Air Cooling

Color : Blue

Desktop Laser Marking Machine

Minimum Order Quantity : 1 Unit

Condition : New

Cooling Mode : Air Cooling

Laser Type : Fiber Laser

Color : Blue and White