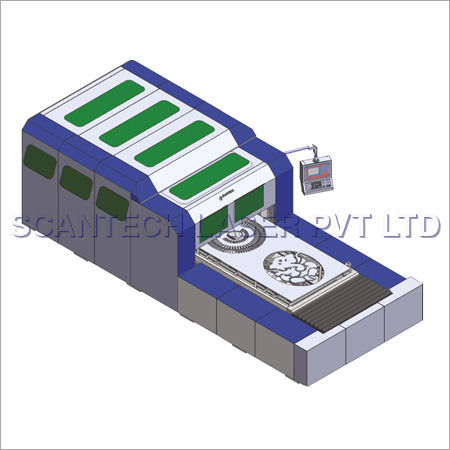

Rotary Cutting System

Rotary Cutting System Specification

- Technology

- Rotary CO2 Laser Cutting System

- Phase

- Single Phase

- Power

- 100W / 150W / 180W (option available)

- Working Area

- 1300 mm x 250 mm (rotary)

- Product Type

- Rotary Cutting System

- Laser Type

- CO2 Laser

- Cutting Area

- 1300 mm x 250 mm (rotary)

- CNC Or Not

- Yes

- Computerized

- Yes

- Automatic Grade

- Automatic

- Cooling Mode

- Water Cooling

- Control Software

- DSP Control System

- Graphic Format Supported

- AI, BMP, PLT, DXF, DST, DSB, JPEG, GIF, PNG

- Control System

- Automatic Control System

- Voltage

- 220V / 50Hz

- Weight (kg)

- 320 kg

- Dimension (L*W*H)

- 2000 mm x 1450 mm x 1200 mm

- Capacity

- High precision and efficiency cutting

- Color

- Blue / White

- Maximum Rotary Diameter

- 250 mm

- Focus Mode

- Manual/Automatic

- Laser Tube Life

- Up to 10,000 hours

- Resolution Ratio

- 0.0125 mm

- Positioning Accuracy

- 0.01 mm

- Compatible OS

- Windows XP/7/8/10

- Table Type

- Honeycomb and Blade Table

- Optional Accessories

- Red Dot Pointer, Auto Focus, Air Pump

- Interface

- USB, Network

Rotary Cutting System Trade Information

- Minimum Order Quantity

- 1 , , Unit

- Supply Ability

- 10 Units Per Month

- Delivery Time

- 1 Months

About Rotary Cutting System

Rotary Cutting System

We are a noteworthy manufacturer, exporter and supplier of Rotary Cutting System that is broadly used in different industries. This is fabricated at our manufacturing unit using supreme grade raw materials under the guidance of skilled professionals to ensure optimum quality. The offered range of Rotary Cutting System is appreciated for compact design, accurate dimensions, corrosion resistance, easy installation and longer service life. This lase cutting machine is stringently tested as per the set industry standards to meet the international quality standards.

Precision Rotary Laser Cutting

Harnessing advanced CO2 laser technology, this rotary cutting system delivers superior accuracy and clean cuts on cylindrical workpieces. With both manual and automatic focus modes and flexible table options (honeycomb and blade), users can tailor the setup to their specific materials and application needs. Its robust construction ensures stability, while the DSP control software guarantees consistent results every time.

Versatile and User-Friendly Design

Compatible with major Windows operating systems and popular graphic formats (AI, BMP, PLT, DXF, DST, DSB, JPEG, GIF, PNG), this cutting system streamlines workflow from design to production. Users benefit from quick connectivity via USB or network, while optional accessories like a red dot pointer or air pump enhance operational convenience and safety.

Built for Industrial Demands

Engineered for high-precision rotary cutting and automatic operation, this system is a reliable solution for industrial-scale tasks. Its spacious working area (1300 mm x 250 mm rotary), robust 320 kg build, and efficient water-cooled laser ensure durability and consistent output. Manufacturers and suppliers in India can depend on this systems automated capabilities and long-lasting performance for increased productivity.

FAQs of Rotary Cutting System:

Q: How does the rotary cutting system achieve such high precision and accuracy?

A: The systems CO2 laser operates with a resolution ratio of 0.0125 mm and positioning accuracy of 0.01 mm. This precision is maintained through the DSP automatic control system and robust mechanical construction, ensuring consistent, clean cuts for intricate designs.Q: What types of materials can be cut with this rotary laser cutting system?

A: This system is designed for rotary cutting on cylindrical materials, suitable for a range of non-metallic substances like acrylic, wood, leather, rubber, and some plastics, making it versatile for signage, art, craft, and industrial applications.Q: When should I use the manual versus automatic focus mode?

A: Manual focus is ideal for handling unique or challenging shapes, while automatic focus is suited to standard or repetitive tasks. The system lets users choose the most efficient focus mode for their materials and workflow to optimize cutting quality.Q: Where can this rotary cutting system be installed for optimal use?

A: It is suitable for installation in manufacturing workshops, fabrication centers, sign-making facilities, or educational labs. Ensure a stable, flat surface, appropriate electrical supply (220V/50Hz), and water supply for the cooling system during installation.Q: What is the process for preparing files for cutting?

A: Design files should be prepared in supported formats (AI, BMP, PLT, DXF, DWG, JPEG, GIF, PNG, DST, DSB) and transferred to the system via USB or network. Users can then select appropriate settings in the DSP control software to begin the cutting process.Q: How does the water cooling system benefit the laser cutting operation?

A: Water cooling efficiently regulates the laser tube temperature, extending its life (up to 10,000 hours), maintaining cutting stability, and preventing thermal damage during extended operations.Q: What are the benefits of using the automatic grade and computerized features?

A: Automatic and computerized controls streamline operations, minimize manual intervention, lower the risk of errors, and improve repeatability. This results in higher efficiency and throughput for industrial users.

- Minimum Order Quantity

- 1 , , Unit

- Supply Ability

- 10 Units Per Month

- Delivery Time

- 1 Months

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Laser Cutting Machines Category

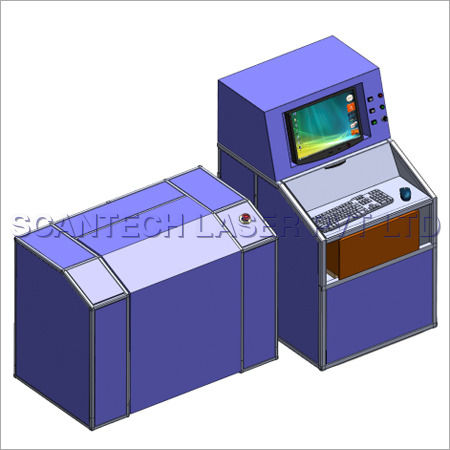

Patriot C Co2 Cutting Machine

Minimum Order Quantity : 1 , , Unit

Product Type : Cutting Machine

Voltage : 220420 Volt (v)

Color : Blue

Patriot F 2D Profile Cutting Machine

Minimum Order Quantity : 1 , , Unit

Product Type : Cutting Machine

Voltage : 220380 Volt (v)

Color : Blue

Industrial Laser Cutting Machines

Minimum Order Quantity : 1 Unit

Product Type : Cutting Machines

Voltage : 220240 Volt (v)

Color : Black

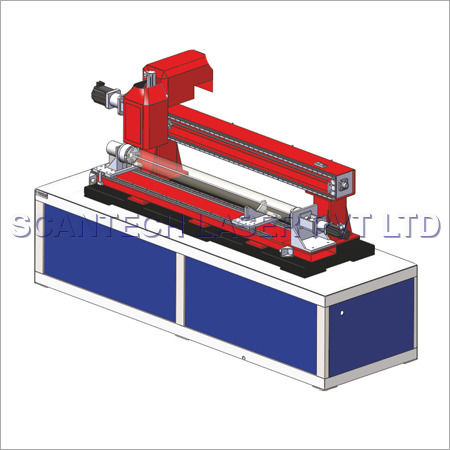

Patriot Fr Fiber Rotary Cutting Machine

Minimum Order Quantity : 1 Unit

Product Type : Cutting Machine

Voltage : 220380 Volt (v)

Color : Other, Red and Blue